Flexible Electronics

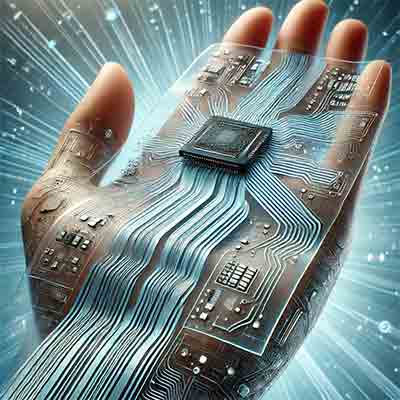

Flexible electronics, also known as flex circuits or flexible circuits, are electronic devices that are built on flexible substrates, allowing them to bend, stretch, or fold while maintaining functionality. This flexibility opens up possibilities for integrating electronics into unconventional and dynamic applications that rigid devices cannot accommodate.

Common Substrates for Flexible Electronics

The choice of substrate material is critical as it determines the device's mechanical, thermal, and electrical properties. Common substrates include:

- Plastic Substrates: Polyimide (PI), Polyethylene Terephthalate (PET), Polyethylene Naphthalate (PEN), Thermoplastic Polyurethane (TPU).

- Metal Foils: Copper, Aluminum, or Stainless Steel Foils.

- Glass and Ceramics: Flexible glass for high-performance applications.

- Paper and Textile: For disposable or wearable applications.

- Emerging Substrates: Nanocellulose, graphene-based films, and other novel nanomaterials.

Applications of Flexible Electronics

Flexible electronics have wide-ranging applications across industries:

- Wearable Electronics: Smartwatches, fitness trackers, and health monitoring devices.

- Medical Devices: Implantable sensors, diagnostic patches, and biosensors.

- Consumer Electronics: Flexible displays, bendable batteries.

- Automotive and Aerospace: Lightweight circuits for dashboards and sensors.

- Energy Harvesting: Flexible solar panels and wearable energy harvesters.

- IoT: Smart labels, RFID tags, and environmental sensors.

- Military: Wearable technology for soldiers, flexible communication systems.

- Healthcare: Smart bandages, physiological monitoring devices.

- Displays: OLED and micro-LED displays.

- Robotics: Flexible circuits for soft robots and robotic skins.

Advantages of Flexible Electronics

- Lightweight and compact design.

- Increased design freedom and versatility.

- Improved durability and shock resistance.

- Potential for cost-effective roll-to-roll manufacturing.